In the dynamic landscape of today’s business world, inventory accuracy levels stand as a linchpin for operational efficiency and the satisfaction of customers. It’s a delicate balance that businesses must navigate, where precise inventory tracking becomes essential in managing resources effectively, curtailing costs, and elevating service delivery standards.

Achieving and maintaining high inventory accuracy levels demands a harmonious blend of strategic planning, the latest technology, and adherence to best practices. Such a multifaceted approach is crucial for thriving businesses in a competitive market.

How to Improve Inventory Accuracy

Continue reading to learn best practices that can improve your inventory accuracy and sustain your competitive advantage.

Utilize Technology to Your advantage

In inventory management, embracing technology is not just a trend; it’s a strategic necessity. Among the many available tools, the best cloud inventory management software offers real-time tracking and insightful analysis of stock levels. This technology streamlines operations, automates routine tasks, and furnishes businesses with the data to make savvy decisions.

The following are vital technological strategies to enhance inventory accuracy:

- Implement barcode scanning: This approach minimizes errors during inventory counts. Scanners quickly capture data, making the process faster and more reliable than manual entry.

- Use RFID tags: For seamless tracking of goods as they move through the supply chain, RFID tags are invaluable. They provide automatic, real-time updates to your inventory system, eliminating the need for manual checks.

- Employ inventory management software: This software tracks inventory and helps analyze stock levels, forecast demand, and schedule restocking. It turns complex data into actionable insights, allowing for more accurate forecasting and inventory optimization.

Adopting advanced technology solutions is essential for businesses aiming to boost their inventory accuracy. By integrating automated systems and data analytics into inventory management, companies can slash error rates, enhance decision-making, and keep pace with the demands of a dynamic market environment.

Conduct Regular Audits

Conducting regular audits stands as a cornerstone for maintaining inventory accuracy. It’s a systematic approach that compares the physical stock with recorded data, ensuring discrepancies are identified and corrected timely. Regular audits keep stock records accurate and provide insights into potential issues within the inventory system.

Here are key strategies to enhance the effectiveness of your audits:

- Schedule cycle counts periodically: Implementing cycle counts allows for frequent inventory checks, segmenting the warehouse into sections, and counting different parts throughout the year. This approach minimizes disruption compared to annual counts and provides ongoing accuracy checks.

- Use variance reports to investigate discrepancies: Variance reports highlight differences between physical counts and system records. Analyzing these variances helps pinpoint the reasons behind mismatches, whether from theft, loss, or recording errors, leading to actionable insights for correction.

- Implement a rotating audit system: A rotating system ensures that all inventory areas are audited regularly without overwhelming staff with a complete inventory count at once. This method spreads the workload evenly and constantly checks inventory accuracy.

Regular audits are vital for keeping inventory records accurate and up-to-date. They offer a systematic way to identify and rectify errors, ensuring that the inventory management system reflects the actual state of the warehouse. By adopting these strategies, businesses can significantly improve their inventory accuracy, contributing to better decision-making and operational efficiency.

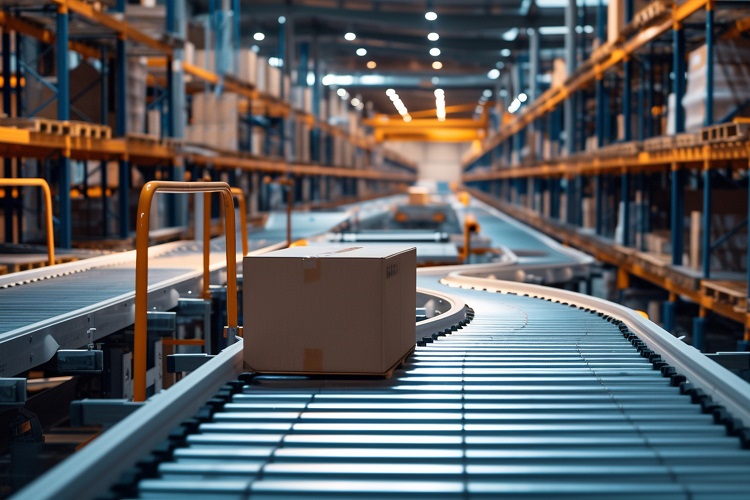

Optimize Inventory Layout

Optimizing your inventory layout is a strategic move that can drive significant improvements in efficiency and accuracy. A thoughtful approach to organizing your storage space ensures that every item is easy to find and count, reducing errors and speeding up the inventory management process. The right layout minimizes the chances of misplaced or overlooked stock, making every operation from receiving to shipping smoother and more reliable.

Below are the details on how to refine your inventory layout:

- Categorize items strategically: Grouping items based on size, frequency of use, or type can dramatically speed up retrieval and restocking times. Consider placing them closer to the shipping area for high-demand items to minimize movement and handling time.

- Implement clear labeling and signage: This is crucial for quickly identifying product locations and navigating storage areas. Clear, consistent labeling ensures employees can find what they’re looking for without unnecessary delays, reducing the risk of picking errors.

- Designate specific areas for different processes: Having dedicated zones for receiving, storage, picking, and shipping helps minimize confusion and streamline operations. This separation ensures that incoming and outgoing stocks aren’t mixed up, maintaining a smooth inventory flow.

How your inventory is organized is pivotal to its accuracy and management efficiency. By categorizing items, using clear labeling, and designating specific areas for different inventory processes, you can achieve a layout that improves accuracy and enhances operational efficiency. This strategic organization of your warehouse space is a fundamental step towards optimizing your inventory management system.

Train Your Team

Training your team thoroughly in inventory management boosts efficiency and helps you adapt to new technologies and methods. Ensuring everyone understands their role in keeping inventory accurate is crucial for your business’s smooth operation.

The following are key aspects to focus on in team training:

- Highlight the impact of inventory accuracy: Ensure employees understand how accurate inventory management affects every aspect of the business, from customer satisfaction to the bottom line. This awareness motivates them to adhere to best practices.

- Provide technology training: Hands-on training with the tools and technologies, such as barcode scanners and inventory management software, ensures that staff are comfortable and efficient using them. Familiarity with these tools reduces errors and increases productivity.

- Regular updates and refresher courses: The inventory management landscape constantly evolves, with new technologies and methodologies emerging. Keeping your team updated with regular training sessions ensures they remain at the forefront of inventory management practices.

Investing in team training improves inventory accuracy and efficiency. A knowledgeable team, familiar with the latest technologies and updates, is vital to effective inventory management.

Conclusion

Exploring the intricacies of inventory management involves a holistic strategy that includes technological integration, thorough audits, optimized warehouse organization, and ongoing team education. These elements are interconnected, each critical to enhancing overall inventory accuracy and efficiency.

As businesses strive to meet the evolving demands of the market, adopting these practices will streamline operations and solidify a competitive edge. The journey towards impeccable inventory management is ongoing, and by prioritizing accuracy, companies can ensure they are well equipped to face future challenges and opportunities.